Extractable & Leachable Studies

In the current scenario where E & L studies have become mandatory to meet the safety requirements of medicines and medical devices, Daicel offers the most comprehensive Studies for various portfolio products and a broad range of packaging materials.

Our team also adopts communication and reporting channels through a project management system to match customer specific requirements. We have a team of scientists who are committed to provide the best solutions which meet the needs of pharmaceutical companies.

Daicel offers

- Vast experience of understanding different formulations, plan and design E & L studies in accordance with current regulatory guidelines

- In house state of the art facility for isolation and synthesis of impurities observed above AET in the leachable studies

- Validated methods for both Simulation studies and Leachables studies

- Risk based approach to E & L Study Design keeping the end goal in mind

- Quick TAT’s

- Extractable & Leachables – Quantitative Studies

Why EL testing : Safety and risk to humans

| Risk associated with administration route | Risk of CCS interacting with drug product | ||

|---|---|---|---|

| High | Medium | Low | |

| Highest |

|

|

|

| High |

|

||

| Low |

|

|

|

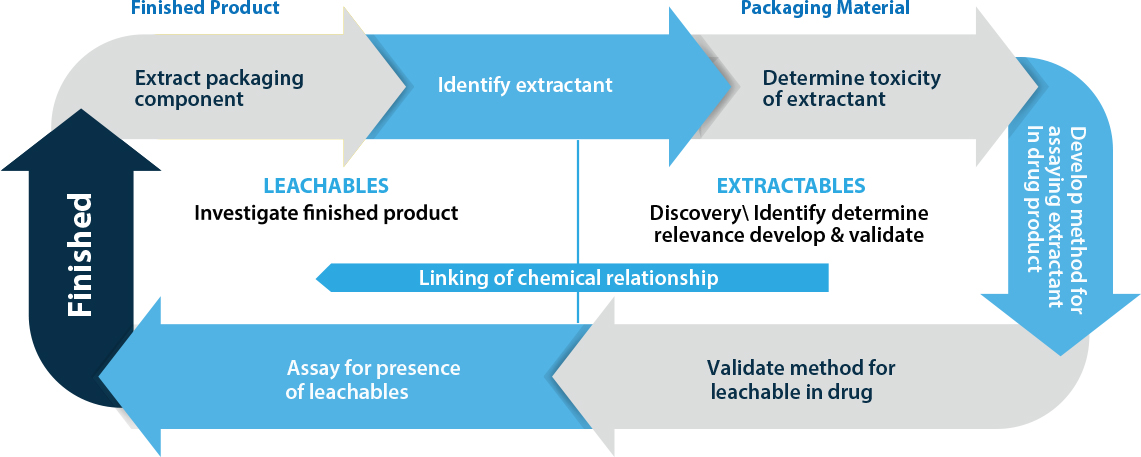

Relationship cycle

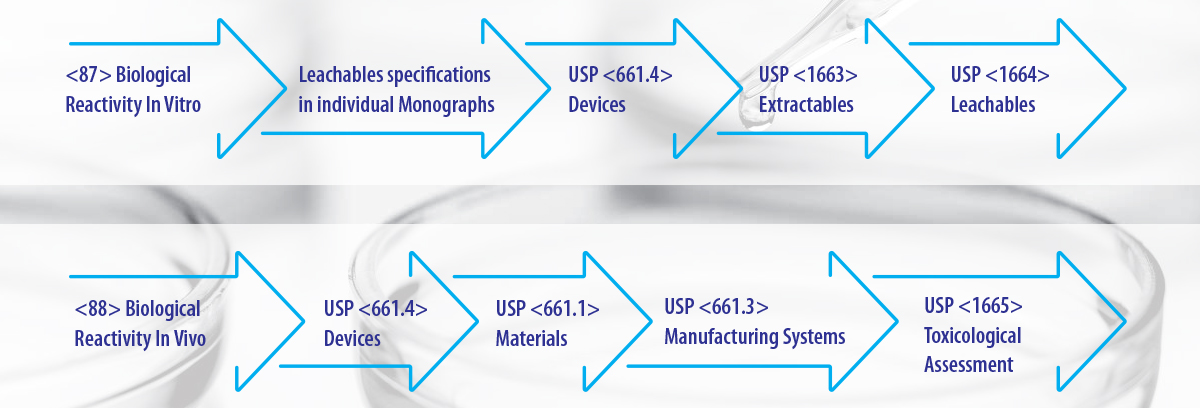

USP Chapters dealing with E & L

Equipped with GC-HS-MS/MS, LC-MS/MS, HRMS, ICP-MS and IC

We ensure compliance with

Key Daicel Capabilities like

Packaging Materials

- Polycarbonate

- Rubber stoppers (Chlorobutyl, Brombutyl)

- Cyclic Olefin copolymer

- Polyvinyl chloride

- Low density polyethylene (LDPE)

- High density polyethylene (HDPE)

- Glass vials

- Closures

- Plungers

Drug Products

- The “4I’s”: Inhalants, Injectables, Infusions, Implantable

- OINDPs (Ophthalmic, pMDI, DPI, Nasal Sprays…)

- Dermal and Topical Applications

- Bio disposables / Single Use Systems

- Vaccines

- Medical Devices

- Label/Ink Migration

- Parenterals

- Peptides/Biologics/Complex Injectables

- Feeding Tubes etc